Hot Rocks Rock: Geothermal Power Generation

electrifying the energy sector by drilling deep holes into hot rock

The newsletter in two sentences: Enhanced geothermal is a flexible clean energy resource that can fill the gaps where solar and wind cannot. I interview Gabriel Malek, Chief of Staff at Fervo Energy and Wilson Ricks, PhD Candidate and Member of Princeton University’s Zero-carbon Energy systems Research and Optimization (ZERO) Lab to learn more.

Problem

Within circles of techno-optimists and clean energy nerds, it seems like solar, wind, and storage dominate the headlines. Pundits point to solar’s insane learning curve and rapid deployment, but the reality is we’re nowhere near a 100% decarbonized economy. The trend lines are promising, but hiccups are inevitable. We’ve seen this recently with billions of dollars being written down and gigawatts of projects getting canceled in the wind industry. To address intermittency in solar and wind, storage is required. Batteries are often lauded as a promising solution, but there is no such thing as a silver bullet. There are still plenty of unknowns that come with anything complex. Supply chain crunches, geopolitical conflicts, and ethical labor concerns pose significant risk.

Solar and wind will still continue to dominate the renewable energy mix, but different, complementary types of energy are needed. A clean, reliable grid needs both variable energy sources that are at the mercy of Mother Nature and controllable energy sources that can be dispatched on a dime. The intermittent resources fluctuate over time which results in demand changing at a high rate. Therefore, energy sources that can ramp up and down quickly are needed. Nuclear and coal aren’t efficient in this regard, but natural gas and geothermal are. Choosing geothermal over natural gas is a no-brainer for the emissions, but there’s additional benefits as well. Compared to alternatives like solar and storage, geothermal takes up relatively little land and requires few minerals.

Enter Enhanced Geothermal

The application of the Earth’s natural underground heat for electricity generation has been around for a while. The first geothermal power plant was built in 1904 in Italy and in the US, we’ve had geothermal plants since the 60s. If geothermal has been around for decades, how come it’s not that prevalent today?

A successful geothermal site must have three things: heat, fluid, and permeability. Existing geothermal plants are hydrothermal, meaning they have naturally occurring heat, fluid, and permeability. While it’s nice that little modification is needed to hydrothermal sites, the downside is that they’re geologically rare. There’s only so many places in the world that resemble Old Faithful in Yellowstone.

The next generation of geothermal plants is referred to as enhanced geothermal systems (EGS). An EGS doesn’t come with pre-existing conditions of the three key attributes. With EGS, you pick a location with naturally occurring heat, add your own fluid, and create your own permeability.

Every EGS project starts with site selection. The most promising regions have hotter temperatures at shallower depths because when heat is closer to the surface, you don’t need to drill as deep. So far, most geothermal has been developed near places where we already know it’s very hot. For example, the Ring-of-Fire region which runs along the periphery of the Pacific Ocean and Iceland, where geothermal makes up over 65% of their energy supply. In the US, Utah and Nevada are good candidates and so is anywhere near known hydrothermal sites such as Yellowstone National Park in northwest Wyoming.

However, building geothermal successfully requires more than picking the right spot. Much of the answer to “Why now?” can be attributed to drilling. The ability to drill down and perform hydraulic fracturing changes the game on two of the three key factors, heat and permeability. By being able to drill effectively and create fractures in the rock where fluid can flow, geothermal becomes way more accessible as an energy source. The potential is large. We only need to access 0.1% of the Earth’s heat content to supply our energy needs for 2 million years. In the US, there’s 5 TW of electric generating potential, which is nearly five times the total US generating capacity today.

In theory, geothermal could play a major role in saving the planet, but in reality, we’re still at the very beginning. Like any new and advanced technology, a lot still needs to improve. In the US, geothermal power currently only makes up 0.4% of annual electricity generation. The DOE announced its target of reducing the cost of EGS by 90% to $45 per megawatt hour by 2035. With low penetration rate, high costs, but lots of opportunity, the question is how this all unfold for enhanced geothermal? What kind of talent, capital, and policy is needed to deploy, prove, and scale geothermal?

I initially chose to cover geothermal because of its unique story with the oil & gas industry. For EGS in particular, drilling seems to be the crux of the matter and no easy feat. Fortunately, for decades, one industry has been motivated by trillions of dollars to innovate on drilling technology. The narrative that critical drilling innovation will be borrowed and repurposed from the oil & gas industry is compelling to me. Much of what you read online paints the oil & gas industry as the main culprit in the climate crisis and rightly so. But what gets lost in the message is that not everyone and not every aspect of the industry is evil. There’s a lot of Houstonians employed at ExxonMobil, Chevron, and Shell that simply want to support their families and don’t actually want to burn the planet down. One oversimplification I observe with the transition of fossil fuel jobs to clean energy jobs is assuming that a coal plant worker can magically switch to becoming an electrician. It’s not a 1:1 shift. Perhaps there’s a more easeful transition that can be made from oil well driller to geothermal well driller. And maybe, just maybe, the transition to a decarbonized energy sector will involve a massive transfer of talent, capital, and drilling expertise from oil & gas to geothermal.

Introducing Gabe and Wilson!

Gabriel Malek is Chief of Staff at Fervo Energy, a startup building enhanced geothermal systems. In November 2023, Fervo unveiled its first-of-its-kind power plant in Nevada which powers Google’s data centers there. In August 2022, Fervo raised $138M in funding led by DCVC. Gabriel began his career at Environmental Defense Fund and then went on to serve as Deputy Chief of Staff for Mark Carney, UN Special Envoy on Climate Action and Finance.

Wilson Ricks is a Mechanical & Aerospace Engineering PhD Candidate and a Member of the Zero-carbon Energy systems Research and Optimization (ZERO) Lab at Princeton University. His current focus is on evaluation of emerging clean energy technologies and energy policy design. Wilson has also interned with the U.S. Department of Energy and Breakthrough Energy.

The rest of this newsletter includes responses from my interviews with Gabe and Wilson. Together, we discuss:

Historically why there hasn’t been more geothermal

Geothermal drilling

Site selection

EGS as a form of energy storage

The flexibility of EGS to fill energy market gaps

and more. Without further ado, let’s get into it 👇.

What problem is Fervo Energy solving and how are you all solving it?

Gabe: Fervo is trying to support full grid decarbonization through next-gen geothermal. I'd say maybe the sub problem that we're trying to solve is we're trying to make geothermal scalable and cheap enough to play a meaningful role in the last stretch of decarbonization for the power sector. If wind and solar and storage can get you 60 to 80 percent of the way there, how can we make sure the geothermal fills that remaining gap to ensure reliability, affordability, and sustainability in power consumption? We're doing that by applying proven oil and gas technology from shale, so horizontal drilling and hydraulic fracturing. We're applying that to geothermal development to ensure reliability.

Historically, what are some reasons why there hasn’t been more geothermal?

Gabe: The reason attempts at enhanced geothermal systems have failed is because the geothermal industry has used largely outdated drilling technology. Imagine trying to code something really complex on a computer from 1970. You wouldn't be able to generate the latest and greatest in AI or machine learning. The same is true in hard tech and geothermal. If you're using a drilling rig and frack plugs and wireline logging all from the 1980s, but the drilling innovations have advanced substantially over those decades, then you're not going to be able to solve those hard problems that come in geothermal reservoirs, which are higher temperature, higher pressure, and harder rock than you find in shale oil and gas.

That gets to geothermal's history as an industry. A lot of geothermal developers started off as power plant manufacturers. Then they decided to vertically integrate and create a customer base using the technology they already know how to build. These are companies with no drilling expertise entering into a field that's largely dependent on drilling success.

Many of the failed attempts were by firms without much drilling background, trying to make the drilling side of the business work when really their expertise was in power plants. Fervo's innovation is essentially closing the technology gap between oil & gas and geothermal. We know this advanced subsurface data analytics technology and drilling technology exists. It's been used time and time again in upstream oil and gas. All we need to do is to transfer that to geothermal, and if we can close that technology gap, then we should see as solid results as we've seen in shale oil and gas.

Drilling seems like the centerpiece. I think people in climate including myself don't know much about drilling. Perhaps there’s an aversion because it comes from Oil & Gas. So what are some of the milestones that have been made in drilling?

Gabe: So it's funny. I'll share a quick story from earlier this year. We brought a reporter out to our site in Nevada where we have our commercial pilot project. This person was walking around the site, looking at the drilling rig, and marveling at some of the technology that they saw including the big computer monitors where we're analyzing rock formations, temperature, and pressure in real time.

The reporter said to us, “It's really remarkable how much you all have innovated as Fervo in just a few years.” And we're sort of laughing to ourselves because Fervo didn't develop any of that technology that the reporter saw. This was all oil and gas. And I think the reason why climate reporters often overlook this innovation is because we see oil and gas as the old, dirty form of energy, and that can often shroud just how sophisticated oil and gas drilling has gotten.

To answer your question more directly, the biggest innovation was hydraulic fracking to ignite the shale oil and gas revolution. As a country, we were at a point where we thought we were going to have to start importing a ton of oil and gas from the Middle East because we thought we were reaching peak supply.

Now nobody talks about the peak supply, it's all a question of peak demand, because hydraulic fracking unlocked hydrocarbons in basins that were previously considered inaccessible. Such as the Permian Basin in West Texas, the DJ Basin in Denver, the Bakken in the Dakotas, and of course, the Marcellus in Pennsylvania and New York.

All of those became hotspots for oil and gas development because you no longer had to go toward a traditional reservoir. You could go to a reservoir that's mostly rock, create fractures in that rock, and then access the hydrocarbons that were trapped in small permeable areas. After you have that main innovation, subsequent innovations follow. So the PDC drill bit — the development of that type of drill bit that can drill efficiently through rock. That works incredibly well in shale, but we're actually using PDC drill bits in geothermal because we found that they can actually drill through granite, which is even harder than shale.

Then you have a whole suite of data analytics tools that didn't previously exist. We line our wells with distributed fiber optic cables. Those fiber optics allow us to map pretty precisely where fluid is flowing in the reservoir using acoustics. And oilfield services companies that we work with like National Oilwell Varco or Schlumberger, or Halliburton have sophisticated software tools where we can track our drill bit in real time 8,000-10, 000 feet below the earth. We can see how fast it's spinning and understand what downhole pressure exists. We can understand what the fluid flow back rate looks like.

Drilling seems crucial since most natural hydrothermal resources are already tapped into. What bottlenecks are there in drilling? How easy is it to repurpose drilling innovations and the physical equipment from O&G?

Wilson: There has actually been quite a lot of advancement in geothermal drilling lately. New polycrystalline diamond drill bits have allowed drilling operations at the Utah FORGE site to progress four times faster than what had been assumed to be the state of the art in hard rock drilling just five years earlier. The advances in horizontal drilling and hydraulic fracturing in the O&G industry over the last decade have also been nothing short of revolutionary, and though there is some learning that needs to occur when applying these techniques to EGS, the fact that they have been de-risked elsewhere is huge. One of the main challenges in using off-the-shelf drilling equipment for EGS is the higher temperatures, as much of this equipment was simply never designed to operate in those conditions. But that's more a matter of there never having been a need to develop high temperature equipment before than it being an enormous technical challenge.

What are the major steps in developing an enhanced geothermal system?

Gabe: We have a process that maps development of a project from idea generation to selling power to a power buyer. It starts with identifying acreage to lease. We have a general sense of where the best geothermal acres are in the US, but when we go the next layer deeper, we're trying to understand the temperature gradient, that's the key piece of information.

So, how deep do you need to go to hit around 190 degrees Celsius? The shallower you can hit that temperature, the better that prospect is going to be, because you don't have to drill as deep and costs are lower. Our first phase is all of that subsurface analysis. Without doing any drilling, we're trying to understand whether there are any existing data sources that can help us figure out that temperature gradient and what the geologic profile of that resource might look like. We're using well logs that oil and gas companies have collected if they've tried to do any exploration in that region before. Sometimes you can find that data through a university. Sometimes you have to buy that data from a company. But we'll collect that data and we'll then make a determination on how deep you have to drill to hit the right temperature for our development. If we think we've found an attractive depth, then we will lease that acreage, either from the federal government, state governments or private leaseholders. Most of our acreage is on federal land because it's in the Western US.

After we've leased that acreage, we go into the next stage of development. We are still just focused on diligencing that resource, but now we're starting to go out to the field, we're filing permits to begin exploration drilling, doing surface studies, and running gravity and magnetic surveys. These are all things you can do without drilling and they give you a sense of what the rock formation might look like. At the same time, we’re having conversations with potential power buyers because we don't want to start drilling until we've lined up a buyer for this resource. It's just too much capital on the line to start drilling without knowing that you're gonna have a buyer. By the time we've reached the end of the second stage, we feel confident enough in the resource that we want to start doing exploration drilling and we've secured an offtaker through a power purchase agreement.

That takes us to stage three where we're doing exploration drilling. There you're just getting high fidelity information about the resource because you're going to the required depths and you're seeing whether the heat is really there. We’re completing the well, which means we're fracking the rock and flowing water between the injection well and the production well to see if the wells connect the way that we expect. Once we've drilled a few well pairs and connected them, then we go to full on development.

The final stage is all about drilling wells. It almost becomes a manufacturing process. Each well is going to look pretty similar to the next, and you're rinsing and repeating, drill, drill, drill. Simultaneously, we're starting to construct the power plant. We're using off-the-shelf organic Rankine cycle technology. The geothermal industry has historically been strong with power plant manufacturing. Throughout this fourth stage, we're finishing the drilling process and building the power plant simultaneously. By the time we complete this final stage, we have a full project that can connect to the grid and sell power.

Why 190 degrees C in particular?

Gabe: That temperature profile and hotter temperatures allow for economic electricity production given existing power plant technology. Cooler temperatures would yield suboptimal/uneconomic electricity production.

What site surveying data are you looking at?

Gabe: The data that we can access ranges in quality. It's hard to say with a broad brush. There are some locations where the most recent data that we can get our hands on is from an old oil well that was drilled near there in 1980. There are others where there was exploration taking place just a few years ago and we can collect that information and feel pretty confident in it. So it depends. That's why the critical stage for us is always going out to the field and doing those gravity and magnetic surveys ourselves and then ultimately drilling a test well and seeing how it turns out because you just don't know fully until you try.

There was an exciting announcement a few weeks ago from Project Innerspace, a geothermal industry association and research group, and they just announced a collaboration with Google to publish a Google Earth equivalent for the subsurface for geothermal. That will hopefully give the public more clarity on where geothermal exists.

How will the role of identifying and validating site selection evolve over time?

Wilson: Site selection will always be very important, though right now it is arguably easier since there are a known set of conventional hydrothermal sites that could host EGS. As those run out, EGS development will need to go further afield and site discovery and characterization will become increasingly important (and costly). One advantage is that unlike conventional geothermal, where identification of a site can lead to maybe a few tens of megawatts of development, discovery of a good EGS basin could enable gigawatts of development in that area.

What are the co-benefits to developing geothermal power plants?

Gabe: We believe that geothermal can and should be core to economy wide decarbonization. We think the best way to get geothermal there is to start by de-risking power development. If we can sell our power to credit worthy utilities, then over time we can start selling to more creative buyers. We agree from a technology perspective that geothermal has the right attributes to fit into a lot of other decarbonization initiatives, whether it's direct air capture, hydrogen, sustainable aviation fuel, or industrial greenhouses.

All of these processes require power and they require heat. Geothermal is differentiated from other renewables in that we can provide both power and heat. We've actually gotten a grant from the Department of Energy for its DAC Hubs initiative, and we were the only power developer that was the lead applicant for DAC Hubs award and ultimately received it.

Our reason for applying to DAC Hubs is because transmission is a huge constraint for renewable power developers. We don't always want to have to wait in the interconnection queue to be able to sell our power to an offtaker and we know that DAC needs a lot of power and also heat. So let's create DAC hubs around strong geothermal resources because heat and power will be, in the long term, the highest costs for DAC developers.

Even with Fervo’s project in NV coming online, much of EGS seems theoretical. What are the biggest bank-for-buck ways to close the gap between theory and reality? Is it as simple as just building more real, full-scale sites?

Wilson: Right now the name of the game is demonstration projects and funding to that end. The pilot in NV was an important step, but for energy offtakers and financiers to take EGS seriously they need proof of successful deployment at the scale of hundreds of megawatts. Drilling an initial batch of projects successfully, at scale, and with consistency will be key to unlocking financing, policy support, and cost reductions via learning. But of course, the earliest demonstration projects will also have the highest capital requirements and the most risk associated. This is where government initiatives like the DOE's Office of Clean Energy Demonstrations and Loan Programs Office have typically come in to support other technologies, though at the moment there's relatively little funding dedicated to EGS specifically.

Right now, it seems like the main bottleneck is in constructing EGS projects (which includes getting the funding). When do you think we’ll approach the limit on known, promising candidates for site location?

Wilson: It depends how you think about limits. Because subsurface heat is such a variable and ultimately uncertain resource, I think site identification and better resource mapping will be important at all stages of deployment. At any given time you want to be targeting resources that are shallowest, hottest, and closest to demand. Even though there's a huge amount of resources out there, the value of finding the very best of it will always be significant. Regarding known sites, it seems likely that most early EGS developments will target the periphery of known conventional geothermal areas. That could likely support a few gigawatts of EGS nationally, but to unlock the theoretical terawatt-scale potential of the technology you really need to get down to greater depths (4+ km) where there are huge volumes of high-temperature rock spread over large swaths of the country. Exploration will definitely be key to identifying areas where this deep geothermal resource is highest quality.

You said on the Volts podcast, “The costs kind of decrease with higher temperature very quickly, and they increase with lower temperatures.” At a high level, what would an optimization function between drilling (in depth and complexity) and temperature vs. fluid vs. permeability look like?”

Wilson: The tradeoff between depth and temperature is very interesting, as costs of drilling increase substantially with greater depths, but so too does the temperature of the resource. For this reason the supply curve ends up looking flatter than might be initially expected, as the higher cost of deep drilling is offset by the greater productivity. In general sites where you get high temperatures at shallow depths (e.g. near hydrothermal features) will be the most desirable. Permeability and fluid presence are less important for EGS projects, but they are generally nice to have.

How stable are EGS sites when it comes to temperature, fluid, and permeability? How should project developers / investors think about risk?

Wilson: This is one of the major unknowns that needs to be addressed through demonstration projects. There has been a lot of simulation work done to characterize the long-term response of EGS reservoirs (especially how long it will take to deplete their heat content), but at the end of the day we need real-world data to increase certainty.

What are the second order effects of fracturing rock to create permeability? Critics of geothermal may point to this as a potential risk.

Wilson: The main risk is probably induced seismicity, and preventing this is a key condition of successful EGS demonstrations. One bright side is that in O&G fracking, most of the seismicity actually comes not from the fracking itself, but from the re-injection of wastewater that needs to be pumped back out of the well and deposited somewhere else after the treatment. EGS can just keep the fracking water in the well and use it as the basis for the system's working fluid, so re-injection isn't an issue at all.

The potential of EGS to also include energy storage via fluid manipulation is fascinating. Especially since it’s kind of “built-in”. How does this compare to other forms of storage like batteries? And what are the unknowns?

Wilson: Our modeling and simulation work suggests that EGS flexibility could enable thousands of hours of energy storage at efficiencies comparable to those of lithium-ion batteries, and significantly higher than those of most competing long-duration storage technologies. The primary constraint on this storage is the need to build an EGS power plant in order to utilize it, and so the major risks are the same as those that remain for EGS as a whole: Can it be engineered consistently and with good long-term reservoir integrity and thermal/hydrological performance? For storage specifically, the biggest unknowns have to do with the subsurface characteristics of a given site: what is the permeability, how hydrologically confined is the reservoir, what are its dimensions etc. These parameters can vary by quite a bit, though our research showed that the ultimate value of flexible EGS is not terribly sensitive to these variations.

How much modification can be made to a site once it's constructed? With a utility scale solar plant, you can relatively easily make repairs, recycle panels, etc., but it seems like with EGS, you have one shot to get it right.

Wilson: This is an important thrust of current R&D efforts. There is certainly the possibility that reservoirs could be expanded or modified after being created (e.g., cutting off specific flow pathways that cool down too quickly), but for the most part these exercises remain theoretical while developers work on getting the basic reservoir engineering right in the first place.

You previously said “This is a levelized cost in the $50 to $60 to $70 range compared to wind and solar that are at like sub-$20. Even though the costs are high, the flexibility raises the value by so much that it still becomes a good economic proposition.” Does the math make sense because you’re assuming that you can ramp up/down tightly coupled to the real-time market price of electricity?

Wilson: I'll note that even without flexibility in the picture, the levelized cost of energy is only half the story when it comes to the economics of a technology. You also have to consider the value of the power it generates at the time it is delivered, and a technology that can generate at all times will necessarily hold a higher value than one whose output is concentrated in specific times (e.g. solar). For flexible geothermal, the ability to concentrate even more of its output in times of high power prices is key to its value. The time value of energy is highly variable, so just generating the same amount of power in a different set of hours can have an enormous impact on a technology's economics. We found for example that a flexible EGS technology could cost 37% more than an inflexible equivalent and still achieve the same level of deployment.

The ramping speed is helpful, but the main benefit is really just the ability to shift its generation to times when power is more valuable. Conventional geothermal plants can reduce their power output at any point in time, but the potential generation is just lost when that occurs. For a flexible EGS plant, reductions in generation at one point in time can actually enable greater generation at other times.

It seems like the candidates for sites are predominantly in the west (UT, NV). What does that indicate for decarbonizing the grid for the east coast?

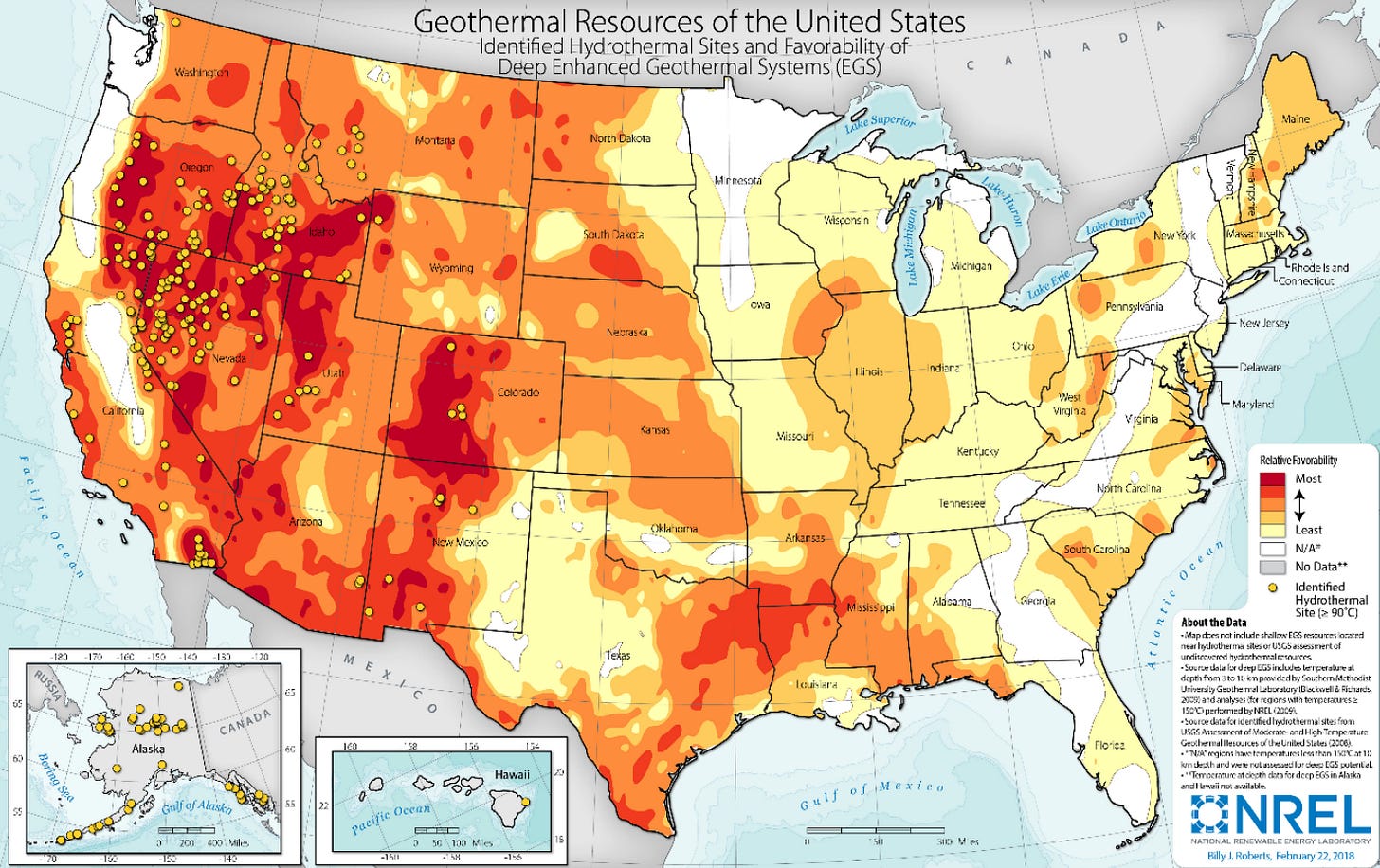

Wilson: EGS will certainly be much more relevant in the West (see the below figure), but there are still regions of the US south and east with some resource potential. Other areas of the world also certainly have large potential (e.g. East Africa), but these aren't nearly as well mapped as the US. If you go really deep (like >10 km) you can find good resource temperatures basically everywhere, but achieving this cost-effectively would likely require a step change in drilling technology. In the meantime transmission will certainly help, but it's still unlikely that we could get away with using only wind, solar and geothermal in all areas of the country/world.

Is it possible to run out of “good” EGS site locations?

Gabe: I think what we're seeing in geothermal is what you see in most subsurface industries. Every time you think you've hit peak supply, you realize through tech innovation on the exploration side that there are actually way more resources than you had previously expected. That was true in oil & gas, it's been true in mining and minerals, and it's already playing out in geothermal.

The 2019 GeoVision report from the Department of Energy put enhanced geothermal potential around 250 gigawatts. Earlier this year, an updated report from NREL upped that number to well over 300 gigawatts. That's not even taking into account resources at deeper depths. I think we'll just continue to see that as more money and more attention goes into geothermal, probably going to be more geothermal potential than we appreciated.

Credits

Thanks again to Gabe and Wilson for contributing to this piece!

If you’re interested in joining Fervo, they’re hiring.

And if you wanna learn more about geothermal, I highly recommend checking out Wilson’s research digest (first link below).